Glass

An AR Glass Blowing Assistant

Glass expedites the challenging process of learning to work with hot glass for beginners, and makes masters more effective by displaying critical information and suggestions to the user through the use of augmented reality.

Problem

Glass blowing takes years to master, and even at a high level critical mistakes can be easily made.

Solution

Visual Feedback

Time

Working with hot glass is an extremely time sensitive practice. Too hot and you lose form, to cold and your glass could explode. This even happens to master glass blowers. Glass gives constant visual feedback on the temperature of the material to reduce errors.

Form

Currently, glass blowers go back and forth between prototypes and the piece they’re creating with calipers to get accurate sizing. This wastes a significant amount of time and heat. This product takes a 3D model input, and projects it onto the end of the punty to save time and reduce failure rate.

Angle

Using the correct angle throughout the glass working process is critical. It’s enormously helpful to have someone more experienced watching you work to help with this. One of the key functions of this product is a guide to help users get the perfect angle of their tool for the form they aim to create.

Features

Physical Meets Digital

Glass combines augmented reality with a physical interface to provide helpful visual feedback while not distracting the user from the form they're creating.

Glasses

Glass blowers always wear safety glasses to prevent glass from exploding into their eyes. A custom pair was developed with a very circular from for this project to carry the theme of the ring throughout the brand.

Physical Interface

Using a digital interface to turn on and off specific functions while working hot glass would be far too distracting as anything that takes attention away from the piece could result in the loss of form. For this reason, a physical interface which can be custom programmed by the user was created for quick function switching. Here they select “Toggle All” which responds to the users action and displays the most critical information to their current state.

Overall Temperature

Knowing the overall temperature of the piece of glass is critical in knowing when it’s safe to change its form and when you need to reheat it. Constant visual feedback is given to inform the user of the temperature of the form reducing the risk of glass explosion and the loss of potentially hours of work.

Regional Temperature

In certain situations (torching, pipe cooling, etc), regional temperature is just as important. This is displayed in a semicircle differentiating it visually from the full circle that indicates overall temperature.

Form

To reduce time measuring with calipers, the form is projected onto the punty. The inner white circle indicates the dimensions that were input, while the outer circle indicates the temperature of the specific region and whether or not it’s safe to change it’s form/needs a reheat.

Grab Tool

In the hot shop, it’s best practice to set up your tools in the same orientation each time. This makes grabbing the tool you’re looking for becomes second nature. Being that this tool is targeted at masters and beginners, a “Grab Tool” assist function can be turned on to help new users more quickly identify what they’ll need for the next step, expediting the learning process. In this scene you can also see the time remaining with the overall temperature monitor.

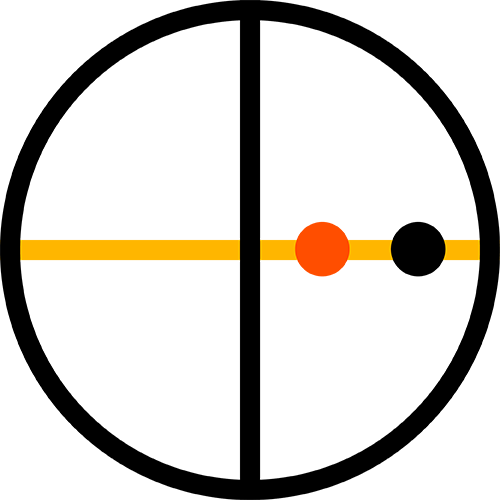

Angle

As previously stated using the correct tool angle throughout the glass working process is critical. The colored axis informs which direction the user is off. The smaller circles on the colored line show how far they’re off, and respond to the current position. The small center circle indicates the depth in which the tool needs to be inserted into the form.

Research

Internal & External

Reasearch was conducted by interviewing experts in the field of glass blowing from Corning Museum of Glass and RIT, as well as through personal experience with glass blowing.

Thanks to:

Corning Museum of Glass

Vignelli Center for Design Studies

Rochester Institute of Technology

David Schnuckel

Corning Museum of Glass

I've been enamored with glass from a young age after visits to CMOG. Over the summer of 2022, I was fortunate enough to assist in a Vignelli Center summer workshop in partnership with Corning. Here I observed some of the world's best glass blowers doing their thing for three days.

After seeing them bounce back and forth from designer's 3D printed prototypes and the form they were creating, the idea for this project was sparked. They all wear protective glasses, so why not take advantage of AR to increase efficency? Forms could be projected onto the end of the punty, and critical information like temperature could be shown to reduce error rates.

Personal Experience

During my time in grad school, I was able to explore the medium of glass first hand with the help of professor David Schnuckel. I noticed that when he was giving me direct instruction as to the angle of the tool, temperature, etc., my work always turned out better. As one person, it's impossible to be over the shoulder of eight students all at once, which also helped inspire this project and its potential functionality.

Takeaways

Temperature, Form, Angle

From my personal experience and field research, I found the most critical pieces of information to creating a successful piece and reducing error are temperature, form, and tool angle.

Form Development

The Ring

Inspired by the rotation of the punty and blow pipe throughout the glass blowing process, the ring was used at a thematic form throughout the brand. Be it the logo, the glasses, or the interface (both physical and digital) the ring aims to unite the full product lineup and create cohesion throughout a number of products.

Conclusion

AR Glass Blowing Assistant

With a customizable physical interface providing pertinent visual feedback, Glass reduces the error rate for glass blowers, and expedites the learning process for beginners.

Thanks for stopping by!

Comittee:

Mike Strobert

Adam Smith

Tools Used:

Adobe Suite

Mocha

Davinci Resolve

Cinema 4D